Effective Strategies for Streamlining Warehouse Inventory and Optimizing Material Handling

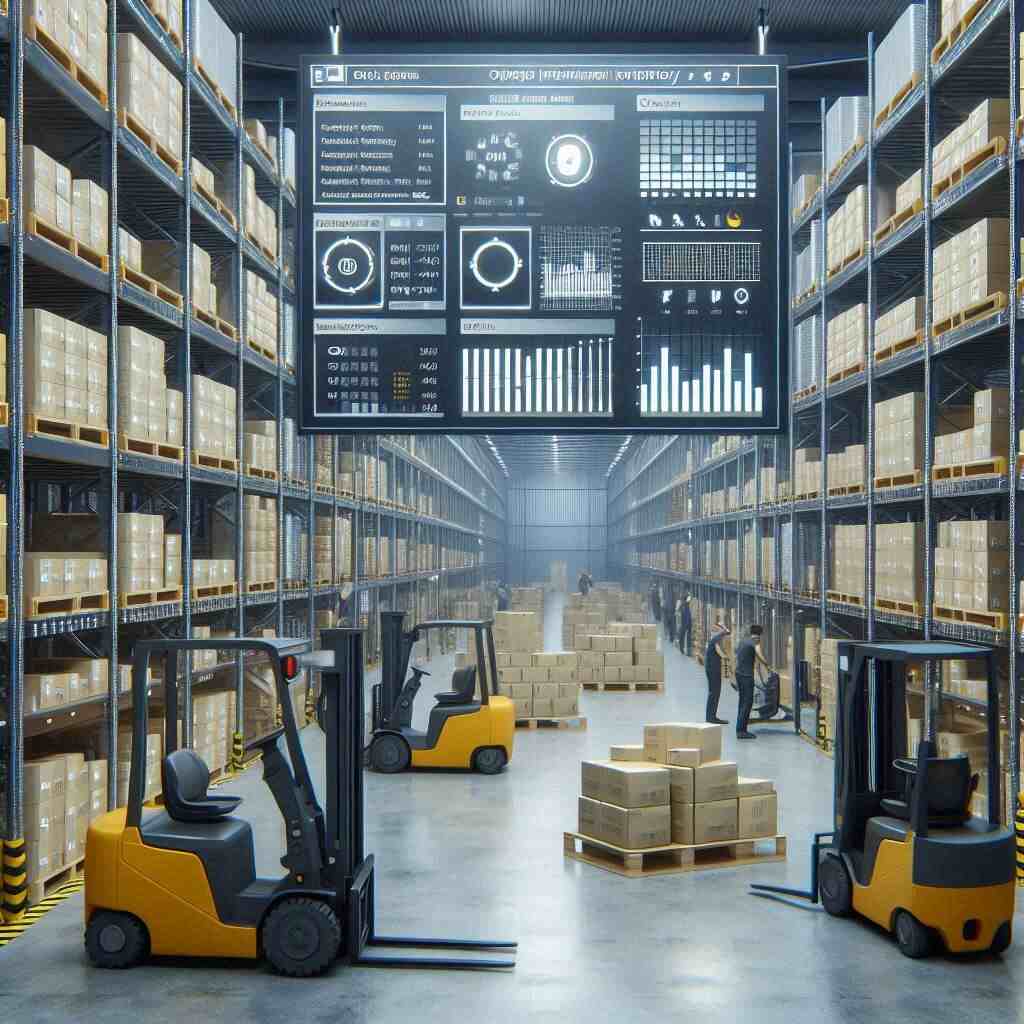

Warehouse inventory management is one of the most crucial aspects of running a smooth and efficient operation. With the growing demands of global supply chains and the increasing complexity of material handling, effective strategies are key to ensuring that goods are stored, tracked, and retrieved in the most efficient manner possible. In this article, we’ll explore some of the most effective strategies to streamline warehouse inventory management, from optimizing storage methods to employing the right technology.

1. Organizing Your Warehouse Layout

The first step in optimizing warehouse inventory management is creating an efficient layout. A disorganized warehouse can lead to increased retrieval times, unnecessary labor costs, and frequent stockouts or overstocking. Therefore, organizing the warehouse layout is critical for both short-term productivity and long-term efficiency.

To begin with, consider grouping similar items together. Items that are frequently picked should be located closer to packing or shipping areas. This reduces the time employees spend walking across the warehouse, making the overall operation much more efficient. Using bins, shelves, and pallets to group products together can also reduce clutter and make finding items quicker.

A clear path through the warehouse is vital. Ensure that aisles are wide enough for forklifts and that there is a logical flow to the storage system, with items often in demand near the front of the warehouse.

2. Implementing Inventory Management Software

Technology has become a key driver of efficiency in inventory management. Modern inventory management software (IMS) can automate many of the tasks that would otherwise be time-consuming and prone to human error. With this software, warehouse managers can track inventory levels in real-time, receive alerts when stock runs low, and automatically generate reorder points for products.

For warehouses handling large volumes of inventory, IMS is invaluable in preventing stock discrepancies and reducing the risk of losing valuable inventory. Real-time tracking allows for more precise demand forecasting and better decision-making, as warehouse managers can analyze trends over time to optimize stock levels.

Furthermore, integrating barcode scanning technology into the software can provide an added layer of accuracy. Barcodes allow warehouse staff to quickly scan and track the movement of goods, reducing the chances of human error while also speeding up the overall process.

3. Adopting Lean Inventory Practices

A lean inventory approach is about reducing waste and improving flow. This philosophy, originally developed in manufacturing, is now widely used in warehouse inventory management to cut down on the holding costs of excess stock and optimize warehouse space.

Just-in-time (JIT) inventory systems are a perfect example of lean practices. By ordering products only when they are needed, companies can avoid overstocking and keep their warehouses organized and uncluttered. While this system works best with reliable suppliers and steady demand patterns, JIT can significantly improve cost-efficiency and make storage spaces more flexible.

However, it’s important to strike the right balance. Too much lean inventory can cause shortages or delays, while too little can lead to overstocking and unnecessary storage costs. A well-thought-out strategy based on actual demand forecasts is necessary for a successful lean inventory system.

4. Utilizing Low-Profile Hoppers for Efficient Storage

One practical solution to save space in your warehouse is to incorporate low-profile hoppers into your storage strategy. These compact, space-saving bins allow you to store materials in a way that minimizes wasted space and makes it easier to store a larger quantity of smaller goods.

Low-profile hoppers are especially useful for warehouses that need to manage bulkier, heavier items that may not fit well on conventional shelving or racks. Their design helps with organization, as they allow materials to be stored in a controlled manner that is easy to access. By using these hoppers effectively, warehouse managers can optimize storage density and ensure that goods are stored in a manner that prevents damage and makes retrieval faster.

5. Improving Picking Methods

The method you use to pick items from your warehouse directly impacts both operational speed and accuracy. There are several ways to improve picking efficiency, depending on the size and type of your warehouse.

For large warehouses, automated picking systems can dramatically reduce the time spent finding and picking goods. These systems use robots or conveyor belts to retrieve items, reducing the reliance on human labor and improving both speed and accuracy.

In warehouses where automation isn’t feasible, adopting a zone picking or batch picking system can still significantly reduce time and labor costs. In zone picking, the warehouse is divided into different zones, with pickers responsible for one specific zone. In batch picking, pickers gather all the items for a batch of orders at once, minimizing the number of trips through the warehouse.

Ultimately, choosing the right picking method depends on your warehouse size, the types of goods you store, and your operational goals.

6. Training Your Staff Effectively

It’s not enough to simply invest in equipment, technology, or storage solutions – your warehouse staff needs to be trained to operate within the new system effectively. Training should focus not only on using the right tools and technology but also on following best practices in safety and organization.

Staff should be taught how to properly use inventory management software and barcode scanners, so they can manage inventory in the most efficient way possible. Regular training also ensures that workers stay updated on the best techniques for handling goods safely and efficiently.

Additionally, consider implementing cross-training programs so that employees can be flexible and help in different areas of the warehouse. This promotes better teamwork and increases overall productivity, especially when a specific area is experiencing a heavy workload.

7. Maximizing Warehouse Space with Vertical Storage Solutions

In most warehouses, space is at a premium. One way to overcome this challenge is by making use of vertical storage solutions. By storing goods vertically, you maximize the available square footage in your warehouse.

Racks, shelving, and palletized storage systems allow you to store items more efficiently by stacking them up rather than spreading them out across the floor. Additionally, vertical storage helps to free up walkways, making it easier to navigate the warehouse.

In warehouses with high ceilings, vertical storage can drastically increase your storage capacity, allowing you to store more goods in the same footprint.

Conclusion

Effective warehouse inventory management involves a combination of well-planned strategies, the right technology, and proper employee training. By optimizing your warehouse layout, adopting inventory management software, and implementing lean practices, you can streamline your operations and ensure your materials are always where they need to be.